Pilot projects completed

Lighting system control and diagnostics

Control and diagnostics technology for the area lighting system is tested at Stasylos railway station. The remote control technology allowed to evaluate the feasibility and effectiveness of smart solutions to reduce energy consumption in LTG facilities, and to promptly identify lighting faults in various railway facilities. The pilot project achieved a 79% electricity saving compared to the previous normal electricity consumption. |

Automated level crossing monitoring

LIDAR equipment has been installed at the Vilnius-N Naujoji Vilnia level crossing, which uses technology to accurately determine the distance, shape and position of an object; the environment is monitored and analysed in real time, and the desired information can be viewed by summarising the digital data in 3D format. |

The results of the pilot project and the lessons learnt can be used to address the implementation of safety assurance measures and operational efficiency measures.

Tests for remote diagnostics of internal systems of passenger trains

The “LTG Link”” passenger train PESA 730ML has been testing a remote diagnostics solution enabling artificial intelligence to detect progressive technical faults. |

The pilot project involved the reading of monitored technical parameters/characteristics into LTG servers and the development of an algorithm for fault identification and classification. Based on the results of the tests carried out, it was decided to consider the pilot project a success.

Testing of video surveillance and passenger information system

The “LTG Link” passenger train PESA 730ML was used to test a centralised, unified and autonomous video surveillance and passenger information system. The pilot project used existing train equipment and systems to computerise control from the driver's cab, install a GPS location and video storage system, install a passenger information system with real-time video transmission, install information displays, sensors for measuring cabin temperature, and security equipment for the system itself. |

On the basis of the results of the tests carried out, it was decided to consider the pilot project a success.

Testing 5G and Starlink equipment

In order to improve mobile and WiFi connectivity on passenger trains, 5G and Starlink equipment was tested on a PESA 730ML passenger train. The pilot project evaluated the reliability, performance, advantages and disadvantages of the equipment, mapped the coverage areas, taking into account the dependence of Starlink connection quality on the satellite positions, and fully assessed the aspects of cyber security, personal data and information systems integration and interoperability. |

Based on the results of the tests carried out, the decision was taken to consider the pilot project a success and to deploy Starlink Internet equipment on all PESA 730ML passenger trains.

Robotic cleaning services for railway facilities

The pilot project evaluated the quality of the new floor cleaning technology in the passenger chamber of Vilnius Railway Station, the performance of the robot cleaner in the presence of high passenger flows or in densely packed rooms with a variety of equipment and objects, the efficiency of achieving performance and other indicators, and the economic feasibility of applying the service in the LTG Group.

Monitoring fuel consumption on railway rolling stock

During the test, remote fuel consumption monitoring equipment was installed in the fuel tank of the freight locomotive to record the actual fuel level in the tank and the location of the locomotive in real time, as well as to assess fuel consumption and find solutions to reduce fuel consumption, and to integrate the monitored data into other digital operational control tools.

Reconstruction of the rail surface profile

Kybartai railway station has tested rail milling technology for the maintenance of railway tracks. |

The pilot project evaluated the application of the technology in technical and financial aspects: restoring the shape and profile of the rail head, ensuring the prevention and detection of rail defects, extending the service life of the rails, and reducing the operating costs for the maintenance of the rails and turnouts.

Solar power plant in the noise attenuation wall

The first pilot project of this type of technology in Lithuania has been successfully completed, during which a double-sided solar power plant was installed on a noise barrier wall near the Kyviškiai-Vaičiūnai railway line. The results of the pilot project exceeded expectations: 16.2 MWh of electricity was generated per year (13.2 MWh was planned), and in 10 out of 12 months, the solar power plant operated more efficiently than predicted at the beginning of the tests. During the project, measurements of noise dispersion caused by rail transport were carried out, which confirmed that the noise level does not exceed the permissible hygiene standards. This means that the wall fully performs its main function – noise reduction. |

The decision to conduct the tests proved to be entirely justified: installing solar power plants in sound-absorbing walls is an effective way to contribute to sustainable electricity production and its expansion, because over its lifetime, a 370 W solar module power plant will help save around 420 tons of CO₂ and can be implemented in noise barriers near existing and newly built railway lines.

Testing of composite sleepers on railway infrastructure

Pilot project location: Joniškis – a truss bridge on the railway section of the state border with Latvia, where 10 composite sleepers and bridge beams were installed.

A specially designed test program included continuous monitoring of the geometric parameters of the upper part of the railway track (gauge width, level, position in the plan) and the bridge structure elements, as well as defects and their impact on the entire bridge structure.

The results show that the composite sleepers and bridge bearings tested during the pilot project are technically reliable and suitable for continuous use in railway infrastructure, and the experience gained can be used to address the issue of replacing existing sleepers with composite ones not only on bridges but also on other railway infrastructure objects, considering their specific characteristics.

Electric Vehicle Charging Points

The opportunity to receive funding through the joint project ‘Installation of Private Electric Vehicle Charging Stations’, led by the Lithuanian Energy Agency, by applying to the announced call ‘Installation of Private Electric Vehicle Charging Stations at Workplaces for Legal Entities’, prompted the LTG Group to install electric vehicle charging stations at its office locations.

This initiative resulted in the installation of 16 electric vehicle charging stations with 32 charging points across locations in Vilnius, Kaunas, Šiauliai, and Klaipėda. Currently, there are 18 such stations at sites managed by the Group.

This infrastructure is available to all employees, enabling them to charge both personal and company electric vehicles.

The project is part of the economic recovery and resilience plan Next Generation Lithuania, funded by the European Union’s economic recovery instrument NextGenerationEU.

Rolling Stock Computing System Diagnostics

DATA DRIVEN INFRA is a digitization program run by LTG INFRA, part of the LTG Group, which plans to use advanced technologies that will fundamentally change the management and maintenance of railway infrastructure. The aim of the program is to transition to predictive maintenance, where faults can be predicted in advance and prevented.

The LTG Group, together with the Austrian company Frauscher, carried out a pilot project for the remote monitoring of rolling stock axle counters located on the railway track, which involved the installation and implementation of software at the Palemonas and Kazlų Rūda stations to achieve the goal of the program.

The data obtained during the trial operation of the technology was thoroughly analyzed to make remote decisions on the need to repair axle counters. The results obtained during the pilot project demonstrated the potential advantages of the equipment: optimization of railway operations, central data storage and secure data management, possibilities for integration into higher-level systems, reduction of downtime through predictive maintenance, more efficient fault repair, and reduction of maintenance costs.

The functionalities of the tested technology have been successfully tested; the pilot project has yielded positive results and expanded existing competencies. It can be said that the use of such a tool simplifies the maintenance of infrastructure facilities and saves maintenance costs.

Pilot projects underway

Automation of freight wagons inspection

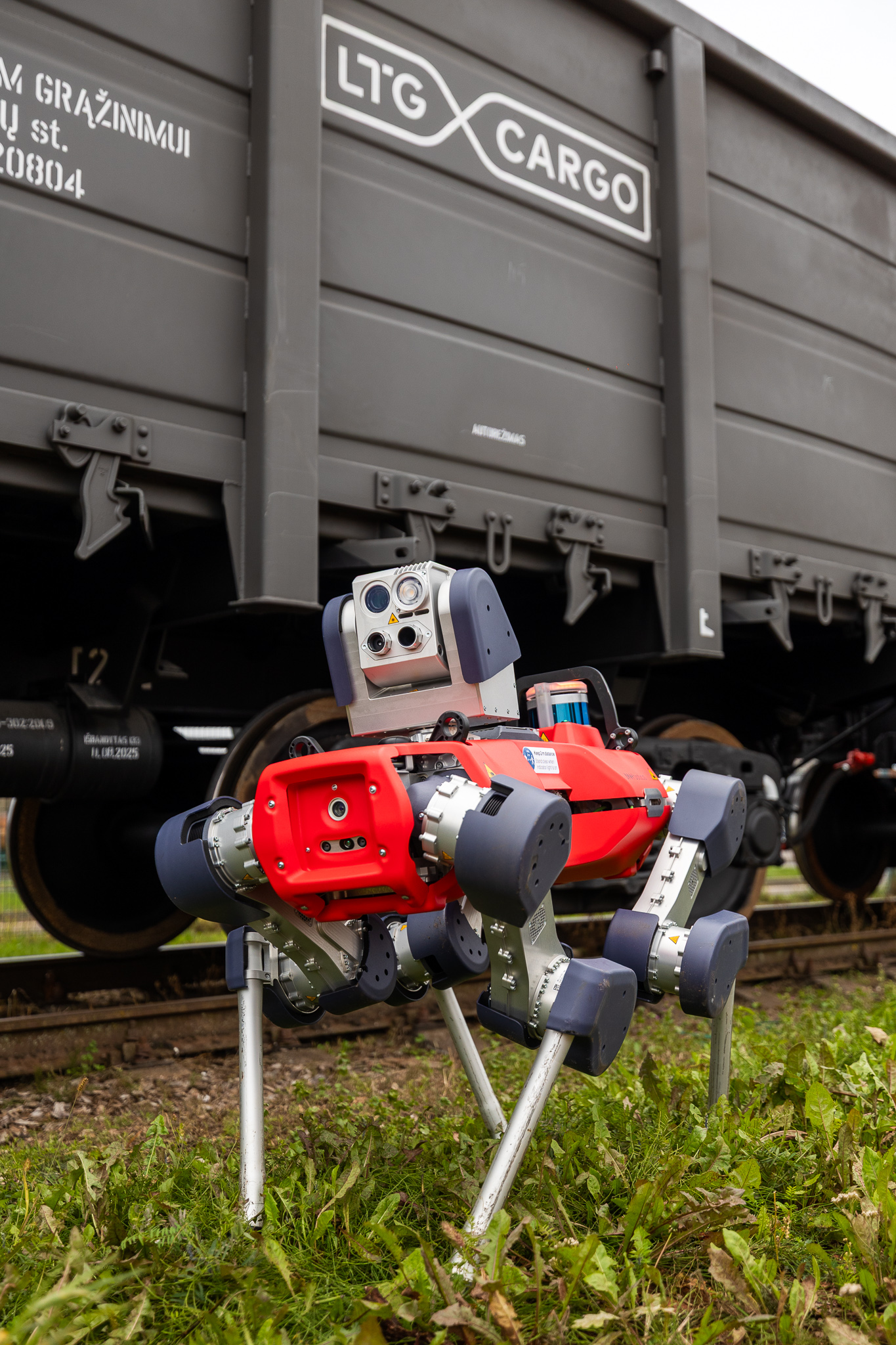

LTG Group company LTG Cargo has launched a pilot project: a specially designed robot will walk around train freight wagons and use artificial intelligence to search for faults in their parts.

The aim of the pilot project is to automate part of the process of checking the technical condition of freight wagons parts, ensuring more efficient planning of work resources and reliable freight transport.

At the beginning of the pilot project, the robot is programmed to be able to capture images of freight wagon parts and components so that a specially developed system can identify various defects and faults.

It is planned that this robot will be able to autonomously walk around freight wagons up to 800 m long and check the technical condition of bogies, axle boxes, brakes, and the compliance of automatic coupling devices and other rolling stock elements with the established requirements.

After the pilot project is completed, a decision will be made on the purchase of additional robots and their permanent use at major railway freight stations, considering the robot's capabilities assessed during the test year and the efficiency of such robotized and automated processes.

Testing of energy storage devices (batteries)

In search of innovative solutions to increase electricity consumption efficiency, the LTG Group has launched a pilot project to test electric storage (battery) technology. The decision to test electricity storage devices was made to make effective use of buildings belonging to the railway infrastructure, test new technologies, and optimize the group's electricity costs.

The first storage devices were installed in the LTG administration building in Vilnius. The results of the six-month pilot project showed that just one function, namely reducing electricity price peaks, yielded tangible results.

The LTG Group will continue the pilot project on a larger scale: it plans to test fully automated and smart battery management technology to assess the possibilities of installing electricity storage devices not only in other LTG Group buildings and equipment, but also on electrified railway sections. To this end, the LTG Group is looking for partners and assessing the potential for installing a battery park at traction substations.

Acoustic deterrents to keep wild animals away from railway tracks

Every year, collisions with wild animals are recorded on the Lithuanian railway infrastructure network. Such incidents not only pose environmental and ethical challenges, but also cause traffic disruptions and significant financial losses, such as the costs of repairing rolling stock and maintaining railway infrastructure or compensating passengers for losses incurred.

The LTG Group has launched a pilot project to test an acoustic animal deterrent. Considering the experience of foreign railway companies and to prevent collisions with wild animals, the pilot project has chosen SIREN7 equipment from a Hungarian manufacturer, which is planned to be installed in almost 30 LTG Link and LTG Cargo rolling stock units.

The results of the pilot project are expected to be evaluated in the second half of 2026.

This initiative is directly in line with the goals set by the United Nations Conference on Biological Diversity and the European Commission. These international organizations are committed to protecting biodiversity, preventing habitat fragmentation, and halting the extinction of endangered species.

Testing of fuel produced from renewable raw materials (HVO100)

The aim of the pilot project is to assess the suitability and safe continuous use of fuel produced from renewable raw materials (HVO100) in railway rolling stock under real freight and passenger transport conditions. The following vehicles are designated for the pilot project: PESA 730ML passenger train, TEM TMH shunting locomotive, and SIEMENS ER20CF mainline locomotive. The planned duration of testing for each vehicle is 18 months. The objectives of the pilot project are to assess the impact of this fuel on the internal combustion engine parts of diesel traction rolling stock, the chemical composition of the materials used, environmental indicators (NOx, CO2, CO, particulate matter, volatile organic compounds, SO2), energy and other rolling stock performance indicators (e.g., fuel consumption). |

The results of the pilot project will be evaluated in the first quarter of 2027.

Testing of employee safety measures (exoskeletons)

The aim of the pilot project is to improve working conditions for employees by using innovative solutions: employees working in rolling stock repair depots, road maintenance and repair, and warehousing will test exoskeletons – special equipment worn on the body to reduce strain.

During the project, three different types of exoskeletons will be tested, selected based on the needs of employees, the functions they perform, and the specifics of their workplaces and processes. The following exoskeletons from the Austrian company SANO Transportgeraete GmbH have been selected for testing: the LiftSuit Auxivo, which is worn like clothing and supports the back and hips, Chairless Chair 2.0, which allows quick, easy, and flexible changes between sitting, standing, and walking positions, and supports the back, hips, knees, ankles, and feet. The third is Hapo Front, which reduces the load on the arms, shoulders, and elbows when performing tasks that require the arms to be held in front of the body for long periods of time.

Based on the personal experience, opinions, and feedback of employees about exoskeletons, a decision will be made on the wider use of this technology in the activities of LTG group companies.

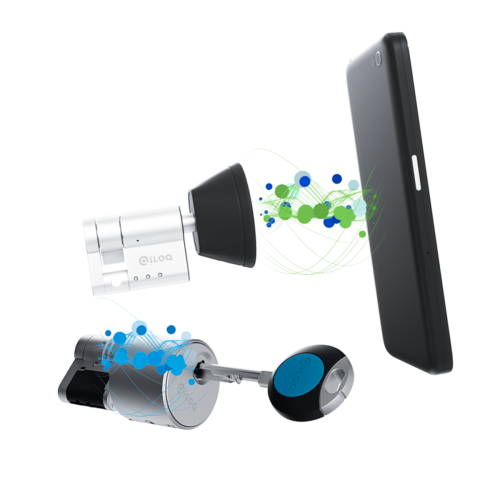

Smart lock testing

The aim of the pilot project is to test a new innovative lock technology in the industrial buildings of Vilnius and Kena railway stations and to assess the reliability of this technology, the technological and economic feasibility and potential of its application in the LTG group.

Smart locks from the Finnish manufacturer iLOQ were selected for testing. Within the scope of the pilot project, software will be installed on employees' computers and partners' mobile devices, which will allow for accurate viewing and control of access to selected objects.